Thomas Leong, an ultrasound engineer and a postdoctoral researcher from the Faculty of Science, Engineering and Technology at the Swinburne University of Technology in Australia, and researchers at the Commonwealth Scientific and Industrial Research Organization have demonstrated the first commercially viable method of making skim milk using ultrasound. The process is expected to be less costly and more sanitary than present methods as well as produce a better product.

The basis of the process is a property of sound that has been known for more than a century. Sound waves that are reflected against a surface form standing waves that have high pressure and low pressure regions called nodes. The difference in energy between the high pressure and low pressure regions of a standing wave can separate particles based on the size of the particle.

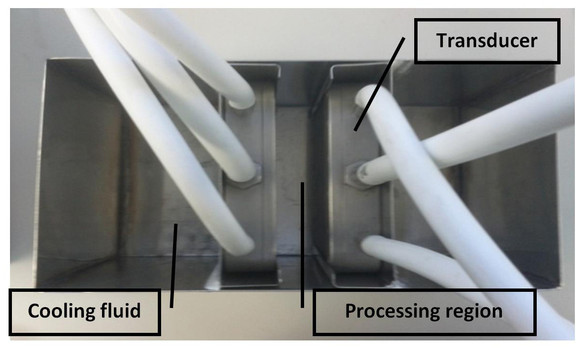

Leong and colleagues fine-tuned the physical apparatus and the acoustics produced by their device to the point that the machine can separate milk from fat at a rate that is faster than present methods. The industrial scale device can produce 8 gallons of skim milk per hour. The quality of the milk and the cream is substantially improved with the ultrasonic method compared to present methods because the device can separate more fat from milk. The quality of cheese and other dairy products made with the skim milk produced with ultrasound is also better.

The researchers are presently shopping their device to dairy product manufacturers across the globe. The advantages are reduced cost, less contact with potential sources of disease producing bacteria, and better tasting products. This device is not new science but it is a unique application of known fact to a new problem.