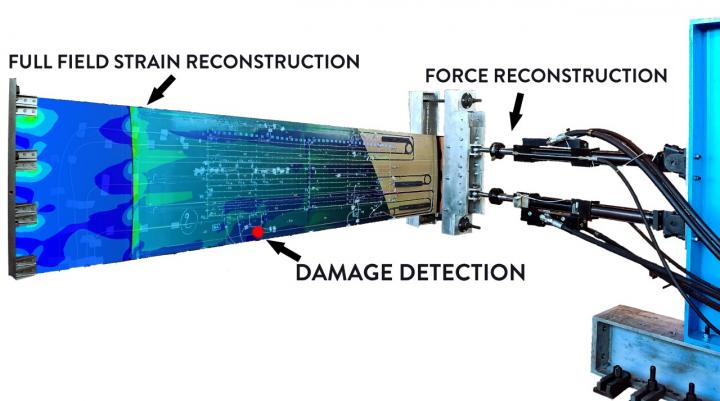

IMAGE: The set-up of the demonstrator at Politecnico lab: a CFRP (Carbon Fiber Reinforced Polymer) full-scale component representative of a RPAS (Remotely Piloted Aircraft Systems) stabilizer, that has been tested both…

view more

Credit: SAMAS

Milan, 8 July 2020 – Using remotely piloted aircraft is one of the main challenges faced by the aerospace industry in recent decades, with a growing number of applications for both military and civilian use. To guarantee the efficient and safe function of these systems, the development of a reliable structural monitoring system is a mandatory phase. Politecnico di Milano, the leading institution of the European project SAMAS – SHM (Application to Remotely Piloted Aircraft Systems- Structural Health Monitoring), has designed, implemented and tested a real-time structural monitoring system that allows to estimate aerodynamic loads and real-time identification of impact on the aircraft in order to instantly estimate any damages.

Unmanned aircraft: opportunities and criticalities

Remotely piloted aircraft systems (RPAS) are used for defence operations in segregated airspaces, and during civilian safety and scientific missions. In the future, the use of these systems will be extended to various application fields, such as agriculture, and to non-segregated spaces, thus increasing the need for efficient platforms that are both reliable and economical. However, the absence of the pilot on-board places some challenges: bird strike or hail impact, high speed impact and accidents during taxing and landing phases are situations that are generally evaluated by the crew. In an unmanned aircraft, they must be identified with an intelligent detection system.

The project

SAMAS – SHM (2017-2020) is a three-year project of the European Defence Agency centred on diagnosis and prognosis of structures made of composite material subjected to aerodynamic loads and overloads caused by low or high speed impact.

The Department of Mechanics of Politecnico di Milano is coordinating the project with its consolidated experience in research on structural monitoring and on estimating damage caused by ballistic impact. The SAMAS consortium also includes the Italian company Leonardo S.p.A. and two Polish entities, the research centre Air Force Institute of Technology and the aeronautical maintenance centre Military Air Works 1.

“The project, launched in 2017, had two main objectives,” says the Scientific Manager, Marco Giglio, Full Professor of Mechanical Design and Machine Construction, Politecnico di Milano. “The first was to create a load monitoring system, made up of both real and virtual sensor nodes, capable of combining in a single and consistent statistics picture the knowledge acquired from a numerical simulation of the structure and data obtained online on-board the aircraft. The second focused on developing an impact monitoring system capable of detecting any impact, of locating it and of quantifying its force in order to estimate the onset of damage on any component of the aircraft.”

Results

The monitoring system developed and implemented by the research team guided by Professor Giglio met both requirements. “The system was tested a few months ago during test flights for load monitoring. For impact monitoring we performed ground tests, in a laboratory setting, on a real-world scale RPAS component late in June,” continues Professor Giglio. “Both technological demonstrators yielded the hoped for results, confirming system reliability. The project reached the end of its research phase with the latter test performed late in June. We have achieved a standard of technological maturity that allows the consortium to dedicate the final semester to industrial applications of the results obtained. The monitoring system we have created will yield safer, more efficient and more effective unmanned vehicles.”

###

TDnews